Since 2019 the food industry has weathered a multitude of crises, from lock-downs impacting people to the shipping crisis impacting the supply of raw materials and a whole range of financial strangulations along the way. The ongoing COVID uncertainty has forced businesses to develop new strategies. Many of these strategies centre around re-shoring, automation and financial hedging.

The situation has become VUCA on steroids, with the critical gaps being how to deal with uncertainty and ambiguity. When we don’t know what we don’t know, how can we plan for it?

Food manufacturers have become used to volatility and changeability, in the past two years, but U.K. food businesses generally work on very small margins and the cumulative impact has eroded vital resources.

- How do food manufacturers pivot to these new-market constraints?

- How can they make changes quickly without impacting existing customer accounts?

- How can they reduce the impacts of market squeeze and supply-chain pressure?

It’s important to consider that the two biggest pinch points in a pivot venture are time and capital, and the elements that consume the most of these are construction and culture change.

Here’s a thought – would a solution that minimises risk and maximises potential be helpful?

The Hermit-Crab strategy is simple but not necessarily easy. It seriously reduces implementation time, minimises capital outlay and provides a reason for change. The Achilles heel of any change initiative is the team not buying into it – What’s in it for them?

- Quick Implementation

- Reduced Capital Outlay

- Improved Workflow

- Improved Use of Space

- Reason For Change

- Opportunity To Engage

This strategy has six key benefits: Quick Implementation, Reduced Capital Outlay, Improved Workflow, Improved Use of Space, Reason for Change and an Opportunity to Engage.

Although, it isn’t as simple as copy and paste exercise. Ensuring that the “new shell” has the right services, access and infrastructure are all parts of the puzzle. There is one fundamental difference; the prospective premises will invariably have a landlord, who is pivotal to the permit to “fit out”.

With the right help, these constraints can be managed comfortably.

A Hampshire premium food manufacturer found themselves in a pickle during a contract bid.

They had been short-listed but had learned that the customer had redefined their commercial objectives and had changed the selection criteria, favouring suppliers who could fit in with these plans.

This food manufacturer had committed too much to the bid already, to consider dropping out, the opportunity would open up a market sector previously unavailable to them.

This business didn’t have time to do things the conventional way.

Red Ocean Review

The engagement began with a Red-Ocean Review and Loose Brick Analysis. Understanding the competitive landscape and identifying potential gaps that had been overlooked or seen as “too difficult” by competitors, fleshed out the key questions; how big, how quickly and what now?

Whilst this business knew their product and had been a premium food manufacturer for a long time, they accepted that they needed to make substantial changes to help them pivot to a new opportunity and a changing business environment.

Their low staff turnover which had its benefits had made “making changes” difficult in the past.

“Loose brick analysis” highlighted that the business landscape was likely to change significantly. With customers’ attitudes and priorities being different, global supply chain disruption taking many months (maybe years) to normalise and commodity costs rising, out of step with inflation.

In short, the new normal would be more constrained, more expensive and more fluid as employees’ expectations and working options evolved.

Doing things differently enabled this client to aggressively position themselves in the bid process and to carve out a niche for themselves in the market (a blue ocean opportunity).

Engaging a specialist in manufacturing engineering and operational excellence, but specifically with experience of delivering manufacturing projects in volatile emerging and 3rd World markets, was a game-changer for this SME.

Factoring for supply chain inconsistency, currency fluctuations, labour and skills shortages, culture clash and increased exposure to geopolitical impacts, within outline planning was a new concept and at times challenging. “The Hermit Crab” strategy, as a solution, provided scope to rethink their business objectives and operational activities.

The ideal “new shell” was defined as an existing logistic space. This choice immediately addressed the current loading and unloading inefficiencies. The conversations with the landlord went much easier than expected. The landlord quoted, “With this level of investment, it seems you’re planning to be around for a long while”. Having a predefined space that was geared to fulfilment enabled the business to maximise volumetric efficiency – fitting more into the available space and improving the workflow.

The modifications to create the production space were relatively straight forward and the time frame for implementation was significantly reduced. This made finding a general contractor to do the fit-out much easier. Removing the bulk of the construction costs made the project substantially cheaper too. Savings eased cash-flow concerns and allowed some capital to be re-purposed for system upgrades, helping the team..

Saving money and strapping up the Achilles heel – A double bullseye!

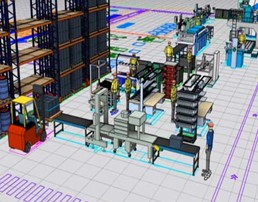

New process layouts and equipment design focused on supporting the client’s objective to penetrate new market sectors, by building in process flexibility and creating a roll-out roadmap for scaling up capacity quickly – allowing them to grow with market share.

Previously they had focused on the making part and now we’re firmly focused on order fulfilment and customer satisfaction – a fundamental mindset shift.

Working with a manufacturing expert registered with UK Business Advisors, gave this client confidence in their ability to deliver the required expertise, and gave access to a pool of experienced professionals that could help the business in other areas.

The process also provided a unique opportunity to design highly efficient processes, import a lean culture and to engage with their staff and supply chain partners to design out problems and garner understanding for hiccups that would invariably happen during the transition.

The results from implementing the Hermit Crab strategy speak for themselves:

- Quick transition – 18-month commercial advantage

- Improved logistics access – improving the overall business flow

- 85% Cost saving – compared to developing a greenfield site

- 18% efficiency improvement – by reducing process bottlenecks

- 20% increased production capacity – from reduced waste and improved workflow

- 30% improvement in process UP-TIME – re-designed to reduce changeover time

- 60% reduction of manual data transfer – machine integrated documentation

- Negligible culture clash – new methods for a new place

- Environmental projects brought forward – great marketing collateral