Well… we never saw that coming.”

How often do you hear that after something has already gone wrong?

The missed deadline.

The system outage.

The supplier failure.

The reputational wobble no one planned for.

Now imagine being able to see it coming—and doing something about it before it hits.

Not perfectly. Not magically. But well enough to:

- reduce disruption to your people and customers

- limit knock-on impacts

- and avoid the extra cost that “unexpected” events so often bring with them

That’s what I think of as hindsight in advance.

Let’s bust a myth first.

There are very few business situations that are truly unpredictable.

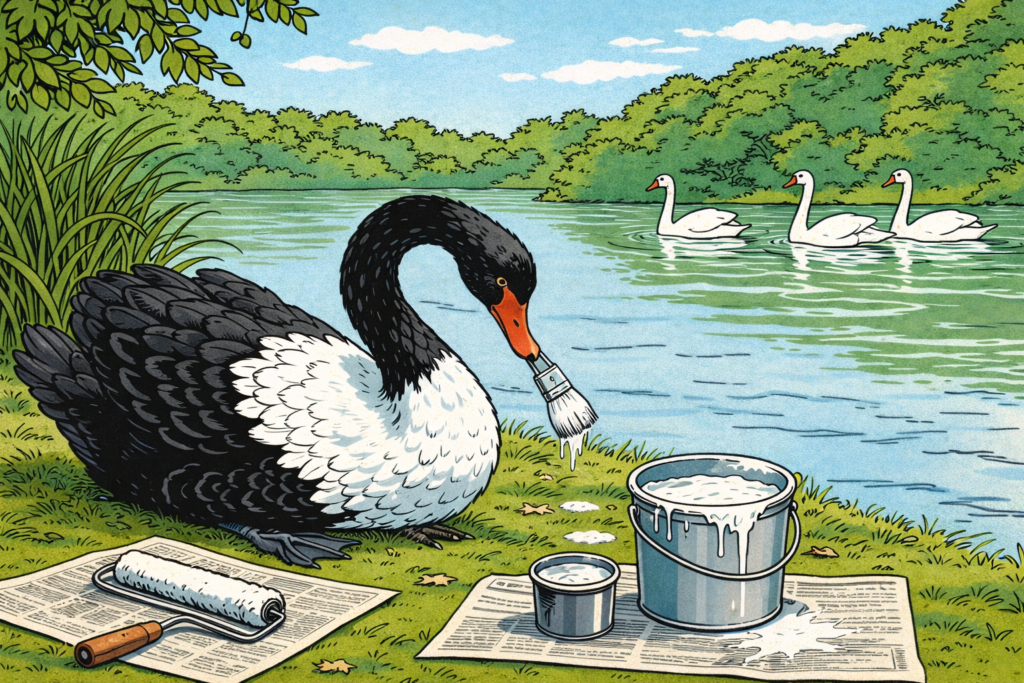

Even the so-called black swans—once the dust settles—are often recognised as having weak signals, assumptions, or warning signs that were visible in advance.

So how do we make the “unpredictable” more predictable?

The short answer: we slow down to think properly—before we’re forced to react quickly.

That means:

- deliberately asking what could go wrong

- translating gut feel into simple ratings so we can prioritise

- and getting into prevention and mitigation early, not post-incident

A simple way to start is by opening up a few uncomfortable but powerful questions:

- What could realistically go wrong here?

- How would we know it’s starting to happen?

- How likely is it?

- If it did happen, how bad would it be?

This kind of structured thinking works at both:

- a macro level (organisational risks, big decisions), and

- a micro level (process steps, handoffs, design choices)

FMEA works

In manufacturing, this approach is well established as Failure Mode and Effects Analysis (FMEA).

But with a little adaptation, the same thinking works just as well in service, technology, and creative environments.

Different context. Same benefit.

Fewer surprises—and more hindsight, in advance.

Where have you seen “unexpected” issues that, in hindsight, weren’t really that unexpected?